Quoting concrete jobs can be a challenging task for contractors and construction professionals. It requires careful calculation and consideration of various factors, such as materials, labor, equipment, and project requirements. Accurate quoting is crucial to ensure a fair pricing for both the contractor and the client, and to avoid any unexpected costs or budget overruns.

To help you improve your quoting accuracy and enhance your business profitability, we have compiled a list of expert tips and best practices. These proven strategies will enable you to estimate concrete jobs more effectively, while taking into account all the necessary components and contingencies.

One of the key tips is to thoroughly evaluate the project requirements and specifications before providing a quote. This includes assessing the type of concrete needed, the volume required, any specific mix designs or additives, and the desired finish. Additionally, you should consider the site conditions, such as accessibility, terrain, and existing structures, which may impact the cost and complexity of the job.

“Accurate quoting is crucial to ensure a fair pricing for both the contractor and the client.”

Learn the Art of Accurately Quoting Concrete Jobs: Expert Tips

Quoting a concrete job accurately is essential for both contractors and customers. A precise quote helps ensure that the project is properly budgeted and that there are no surprises along the way. Here are some expert tips to help you master the art of accurately quoting concrete jobs:

- Understand the Project Requirements: Before providing a quote, it is crucial to thoroughly understand the project requirements. This includes knowing the type and amount of concrete needed, the dimensions of the area to be covered, any special finishes or features required, and any additional services like excavation or reinforcement.

- Factor in Labor and Material Costs: A good quote should consider all the associated costs, including labor and materials. It is important to account for the number of workers required, their hourly rates, and the estimated time needed to complete the job. Additionally, consider the cost of concrete, reinforcement materials, additives, and any other supplies required.

- Consider Equipment and Tools: Concrete jobs often require specific equipment and tools. Make sure to include the cost of renting or purchasing these items in your quote. This may include items like mixers, pumps, finishing tools, and safety equipment.

- Factor in Overhead Costs: It is essential to account for overhead costs, such as insurance, permits, licenses, transportation, and administrative expenses. These costs contribute to the overall pricing of the project and should be included in the quote.

- Account for Waste and Contingencies: Concrete jobs can generate waste and unexpected challenges. It is important to include an allowance for waste material, as well as contingencies for unforeseen obstacles or changes to the project scope. This will help protect your profit margins and ensure that the quote remains accurate.

- Communicate Clearly with the Customer: When providing a quote, it is crucial to communicate clearly with the customer. Make sure to explain the breakdown of costs and any assumptions made. This will help manage expectations and avoid misunderstandings down the line.

- Review and Adjust: Once you have provided a quote, take the time to review and adjust it if necessary. Double-check all the numbers and ensure that they accurately reflect the project requirements. Don’t hesitate to make adjustments or ask for clarifications if needed.

Mastering the art of accurately quoting concrete jobs takes time and experience. By following these expert tips, you can enhance your quoting process and provide accurate quotes that benefit both you and your customers.

Understanding the Scope

To accurately quote concrete jobs, it is crucial to have a clear understanding of the project’s scope. This involves gathering detailed information about the job requirements, specifications, and any unique aspects that may affect the cost and timeline.

1. Site Visit: Begin by visiting the site where the concrete work needs to be done. Take measurements, assess the condition of the existing concrete (if applicable), and note any obstacles or challenges that may impact the project.

2. Client Specifications: Meet with the client to discuss their specific requirements and expectations for the project. Take detailed notes of their desired outcomes, such as the type of concrete, finish, color, and any additional features like decorative elements or stamped patterns.

3. Project Plans: Obtain any architectural or engineering plans for the project, if available. These drawings will provide essential details on dimensions, elevations, and any structural elements that need to be considered when quoting the job.

4. Material Requirements: Determine the quantity and type of materials needed for the concrete job. This includes calculating the amount of concrete, reinforcement (if required), and any additives or admixtures required for the desired finish or strength.

5. Labor and Equipment: Assess the amount of labor and equipment necessary to complete the project. Consider factors such as excavation, formwork, concrete pouring, finishing, and cleanup. Note any specialized equipment or skills that may be required.

6. Permitting and Regulations: Research local building codes, permits, and regulations that may apply to the project. Be aware of any additional costs or timeframes associated with obtaining necessary approvals or inspections.

7. Contingency: Always allow for a contingency in your quote to account for unexpected issues or changes that may arise during the project. This will help ensure that you are adequately covered and can handle any unforeseen circumstances without incurring additional costs.

By thoroughly understanding the scope of the concrete job, you can provide your clients with accurate quotes that reflect the true cost and time required to complete their project. This will help build trust and ensure a successful outcome for both parties involved.

Analyzing the Project Site

Before providing an accurate quote for a concrete job, it is essential to thoroughly analyze the project site. Understanding the conditions, requirements, and constraints of the site will help ensure an accurate estimate of the costs and time involved in the project. Here are some key factors to consider when analyzing the project site:

- Site Access: Assess the accessibility of the site for equipment, materials, and personnel. Consider factors such as proximity to roads, parking availability, and any potential obstacles that could hinder smooth operations.

- Ground Conditions: Evaluate the condition of the soil and subsoil to determine its load-bearing capacity. Different soil types can have a significant impact on the complexity and cost of the project. Conduct soil tests if necessary to gather accurate data.

- Utilities: Identify the location and accessibility of utilities, such as water, electricity, and gas lines. Take note of any existing structures or systems that might need to be relocated or worked around during the concrete job.

- Site Preparation: Determine the extent of site preparation required before starting the concrete work. This may include tasks such as clearing vegetation, removing debris, or leveling the ground. The amount of site preparation needed will affect the estimate and timeline.

- Environmental Factors: Consider any environmental factors that could impact the project. This includes the presence of trees, bodies of water, or sensitive habitats that may require special permits or additional measures to protect them during construction.

- Local Regulations: Familiarize yourself with the local building codes, permits, and regulations that apply to the project. Ensure compliance with all legal requirements to avoid delays, penalties, or potential legal issues.

By thoroughly analyzing the project site, you will be able to provide a more accurate quote for the concrete job that takes into account all the necessary factors. It will also help you identify any potential challenges or risks, allowing you to plan accordingly and avoid surprises during the project execution.

Remember, accurate quoting is crucial for the success of your concrete business, so invest time in evaluating the project site before providing an estimate.

Calculating Materials with Precision

Accurately calculating the materials required for a concrete job is essential for a successful project. By efficiently estimating the materials needed, you can optimize costs and minimize waste. Here are some expert tips to help you calculate materials with precision:

- Measure the dimensions: Start by measuring the dimensions of the area to be concreted. For example, if you are working on a concrete footing, measure the length, width, and depth of the footing. Ensure that your measurements are accurate to avoid any miscalculations.

- Determine the concrete mix ratio: The concrete mix ratio will depend on the specific requirements of your project. Consult the project plans or the engineer to determine the ideal mix ratio. Common ratios include 1:2:4 or 1:1.5:3, which represent the proportions of cement, sand, and aggregate.

- Calculate the volume: Use the measured dimensions and the mix ratio to calculate the volume of concrete needed. Multiply the length, width, and depth to obtain the volume in cubic feet or meters. Adjust the units as needed to match the measurements.

- Consider wastage: It is essential to factor in a wastage allowance when calculating the materials. Typically, a wastage allowance of around 5% is recommended to account for spillage, uneven pouring, and other unexpected factors.

- Convert volume to weight: Once you have the volume of concrete required, convert it to weight. The density of concrete varies depending on the mix ratio and ingredients. Refer to industry standards or consult local suppliers for the specific weight per unit volume of the concrete mix you are using.

- Calculate additional materials: Apart from concrete, various other materials may be required for the project. These can include reinforcement bars (rebar), formwork, gravel, sand, and cement. Calculate the quantities required for each material based on the project specifications.

- Consider delivery and setup: If you are outsourcing the concrete delivery, factor in the additional costs associated with transportation and setup. These costs can vary depending on the distance, accessibility, and specific requirements of the site.

- Create a materials list: Once you have calculated the quantities of all the materials required, create a comprehensive materials list. This list will serve as a reference during purchasing and can help you stay organized throughout the project.

By following these expert tips, you can accurately calculate the materials required for your concrete job. Remember to double-check your calculations and adjust for any specific project requirements to ensure a successful and cost-effective outcome.

Evaluating Labor Costs

When quoting concrete jobs, accurately evaluating labor costs is essential to ensure profitability and client satisfaction. Labor costs can vary based on several factors, including the complexity of the job, the skill level of the workers, and the local labor market. Here are some expert tips to help you evaluate labor costs effectively:

- Understand the project requirements: Before estimating labor costs, thoroughly review the project requirements, including the scope of work, timeline, and any specific skills or certifications required. This will help you determine the number of workers needed and the anticipated time commitment.

- Identify the labor tasks: Break down the project into different labor tasks, such as site preparation, formwork installation, concrete pouring, finishing, and cleanup. Each task may require different skills and time commitments, so it’s important to evaluate them individually.

- Consider productivity rates: Estimating the productivity rates of your workers is crucial for accurate labor cost evaluation. Take into account factors such as the skill level of your team, the efficiency of your equipment, and any potential delays or obstacles that may impact productivity.

- Research local labor rates: Labor rates can vary significantly depending on location. Research the average labor rates in your area to ensure that your estimates are in line with industry standards. Consider any additional costs, such as overtime rates or union wages, if applicable.

- Factor in overhead costs: Don’t forget to include overhead costs associated with labor, such as worker’s compensation insurance, payroll taxes, benefits, and general administrative expenses. These costs can significantly impact the overall labor cost of your project.

- Use historical data: Rely on your past projects and historical data to evaluate labor costs. Analyze similar projects you have completed in the past to get a better understanding of the labor requirements and costs involved.

- Get input from your team: Involve your team in the labor cost evaluation process. They can provide valuable insights based on their experience and expertise, helping you identify any potential challenges or additional requirements.

By carefully evaluating labor costs for your concrete jobs, you can ensure accurate and profitable quotes while meeting client expectations. Don’t hesitate to revisit your estimates as needed and adapt to changes in the project scope or labor market conditions.

Factoring in Equipment Rental Expenses

When quoting concrete jobs, it’s important to consider all the expenses involved, including the cost of equipment rental. Renting specialized equipment can significantly contribute to the overall cost of the project, and therefore, it’s essential to factor this expense into your quote accurately.

1. Identify the required equipment:

Before you can determine the cost of renting equipment, you need to identify the specific items you will need for the job. This may include concrete mixers, saws, pumps, trowels, or any other specialized machinery required for the project.

2. Research rental companies:

Once you know what equipment you need, research different rental companies in your area to compare prices and availability. Consider factors such as the rental duration, maintenance fees, and delivery costs when selecting a rental company.

3. Get rental quotes:

Contact the rental companies you have shortlisted and request quotes for the equipment you need. Make sure to provide them with detailed information about the duration of the rental and any additional services you may require.

4. Calculate the rental cost:

Add up the rental costs from different companies and calculate the average cost. This will give you a rough estimate of how much the equipment rental will contribute to the overall job cost. Take into account any additional expenses, such as fuel costs or rental insurance, and factor them into your quote accordingly.

5. Consider alternative options:

In some cases, renting equipment may not be the most cost-effective solution. If you frequently require certain equipment, it might be more economical to purchase it outright rather than renting it repeatedly. Evaluate the long-term costs and benefits to make an informed decision.

6. Communicate the cost to the client:

Once you have determined the cost of equipment rental, make sure to communicate it clearly to the client in your quote. Break down the expenses and provide a transparent explanation of how the rental cost contributes to the overall project cost.

By factoring in equipment rental expenses accurately, you can ensure that you provide your clients with an accurate and competitive quote for their concrete job. This approach not only helps you cover all the necessary costs but also allows you to maintain a profitable business in the long run.

Considering Overhead and Profit Margins

When quoting concrete jobs, it’s important to take into account your overhead expenses and profit margins. These factors will help ensure you are accurately pricing your services and making a profit. Here are some tips on how to consider overhead and profit margins:

- Calculate your overhead expenses: Start by determining all the costs associated with running your concrete business, such as rent, utilities, insurance, equipment maintenance, and office supplies. Add up these costs and divide them by the number of jobs you plan to complete in a given period to get an idea of your overhead per job.

- Estimate the time and material costs: Next, calculate the time and materials required for each job. This includes the cost of concrete, reinforcement, forms, labor, and any additional materials needed. Make sure to consider any special requirements or complexities that may increase the overall cost.

- Add your desired profit margin: Once you have calculated your overhead and job costs, you’ll want to add a profit margin. This is the amount you want to make on top of your expenses. It’s important to set a realistic profit margin that allows you to cover your overhead and make a reasonable profit.

- Consider market prices: Take a look at what your competitors are charging for similar concrete jobs. While you don’t want to underprice yourself, it’s important to stay competitive in the market. Adjust your pricing accordingly, keeping in mind factors like your experience, reputation, and quality of work.

By considering your overhead expenses, estimating job costs accurately, adding a reasonable profit margin, and keeping an eye on market prices, you can ensure that your quotes for concrete jobs are both accurate and profitable. Remember to regularly review and adjust your pricing strategy as needed to stay competitive and profitable in the industry.

Adapting to Market Prices

When quoting concrete jobs, it is important to consider market prices in order to provide accurate and competitive estimates. Adapting your pricing strategy to reflect the current market conditions can help you secure more projects and maximize your profits. Here are some key tips to help you adapt to market prices:

- Stay informed about industry trends: Keep yourself updated with the latest trends and developments in the concrete industry. This includes monitoring the prices of raw materials, labor costs, and any other factors that may affect the overall cost of a concrete job.

- Research your competition: Analyze your competitors’ pricing strategies and compare them to your own. This will give you a better understanding of the market rates and help you position your services accordingly. Consider offering competitive pricing without compromising on the quality of your work.

- Consider supply and demand: Take into account the current supply and demand situation in your area. If there is a high demand for concrete services and a limited supply of skilled contractors, you may be able to charge higher prices. Conversely, if there is an oversupply of contractors, you may need to adjust your prices to remain competitive.

- Factor in your costs: Calculate your costs accurately to ensure you are covering all your expenses and making a profit. Consider the cost of materials, equipment, labor, permits, insurance, and any other costs associated with the job. Be sure to also factor in overhead costs such as rent, utilities, and administrative expenses.

- Offer flexibility: Consider offering different pricing options to cater to different customer needs. For example, you can provide a basic package at a lower price point and offer additional services or upgrades at an additional cost. This allows you to cater to a wider range of customers and accommodate varying budgets.

- Regularly review and adjust your prices: Prices in the market can fluctuate due to various factors, so it is important to review and adjust your pricing periodically. Keep an eye on market trends and make adjustments to your pricing strategy accordingly. This will help you remain competitive and ensure that you are pricing your services correctly.

By adapting to market prices, you can ensure that your quotes are accurate and competitive. This will help you attract more customers and increase your chances of winning concrete projects. Remember to constantly stay informed about market trends and review your prices regularly to stay ahead in the competitive concrete industry.

Communicating Clearly with Clients

Effective communication with your clients is crucial when quoting concrete jobs. Clear and concise communication helps avoid misunderstandings and ensures that both parties are on the same page. Here are some expert tips for communicating with clients:

- Active Listening: When discussing the project with your client, make sure to actively listen to their requirements and expectations. This will help you better understand their needs and provide an accurate quote.

- Ask Questions: If there is any ambiguity or confusion regarding the project, don’t hesitate to ask clarifying questions. It’s better to seek clarification upfront rather than making assumptions that could lead to costly mistakes.

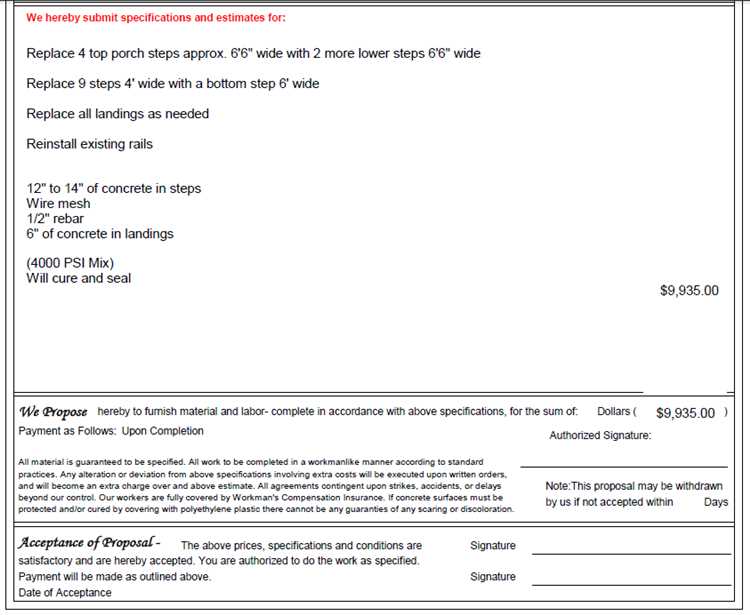

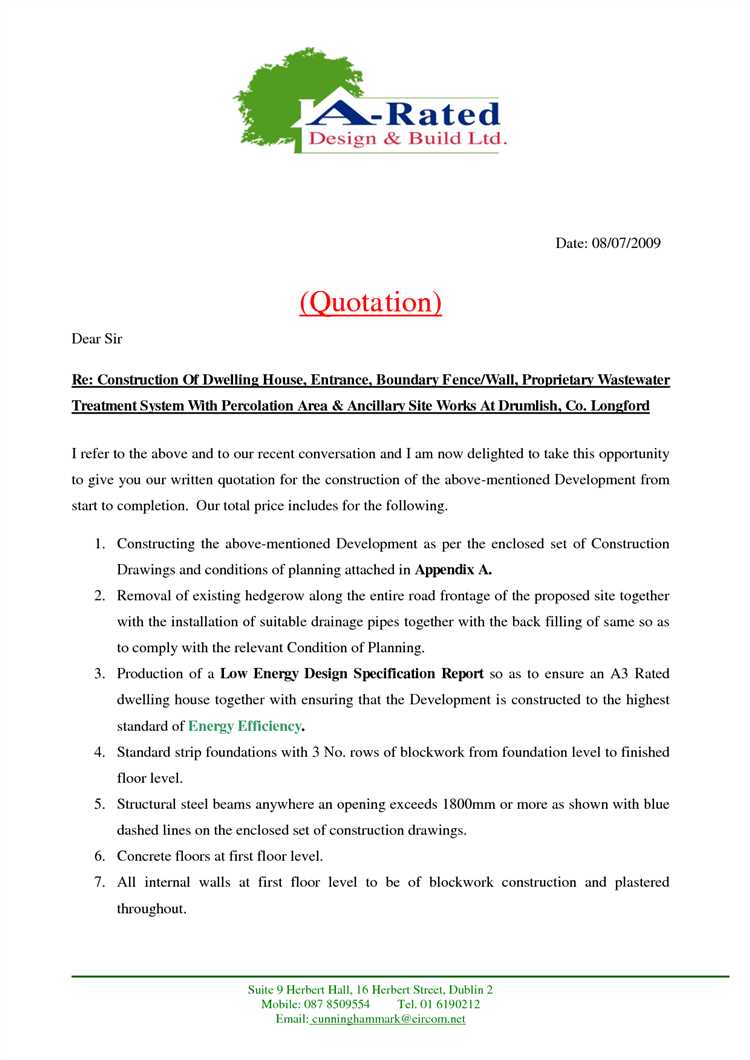

- Provide Detailed Information: When presenting the quote, be sure to include detailed information about the scope of work, materials to be used, and any additional charges or conditions. This will eliminate any surprises or disagreements later on.

- Set Realistic Expectations: Be honest with your client about the feasibility of their project and set realistic expectations regarding timelines and costs. This will help build trust and avoid disappointment later on.

- Document Everything: Keep a record of all communication with your client, including emails, phone calls, and in-person meetings. This will serve as a reference in case of any disputes or misunderstandings in the future.

- Be Professional and Courteous: Maintain a professional and courteous demeanor when interacting with your clients. Respond to their queries and concerns in a prompt and polite manner to build a positive working relationship.

Remember, clear and effective communication is key to a successful concrete job. By following these tips, you can ensure that you are accurately quoting and meeting your client’s expectations, leading to a satisfied and happy customer.

Question and answer:

What are some tips for accurately quoting concrete jobs?

Accurately quoting concrete jobs requires careful planning and consideration. Here are some tips to help you: 1) Measure all dimensions accurately, including length, width, and height. 2) Consider the thickness of the concrete, as a thicker slab will require more materials and labor. 3) Take into account the type of concrete mix needed for the job, such as standard or high-strength mix. 4) Factor in any additional materials or equipment needed, such as reinforcement bars or concrete pumps. 5) Calculate the labor costs based on the complexity of the job and the number of workers required. 6) Consider any site-specific factors that may impact the cost, such as accessibility or special requirements. By carefully considering these factors, you can provide an accurate quote for a concrete job.

How important is it to measure dimensions accurately when quoting concrete jobs?

Measuring dimensions accurately is crucial when quoting concrete jobs. Any inaccuracies in the measurements can result in overestimating or underestimating the amount of materials and labor needed for the project. This can lead to costly mistakes and delays. Therefore, it is important to double-check all measurements and take into account any variations in the thickness or slope of the concrete. By ensuring accurate measurements, you can provide a more precise quote and avoid potential issues during the construction process.

What are some factors to consider when calculating the labor costs for a concrete job?

Calculating the labor costs for a concrete job involves taking into account several factors. These include the complexity of the job, the number of workers required, the duration of the project, and any overtime or additional expenses that may be incurred. It is important to consider the specific tasks involved in the project, such as excavation, formwork, pouring, and finishing, and estimate the time and effort required for each. Additionally, the expertise and experience of the workers should also be factored into the labor costs. By considering these factors, you can provide a more accurate quote for the concrete job.

What are some additional materials or equipment that may be needed for a concrete job?

In addition to the basic materials, such as cement, aggregates, and water, there are several additional materials and equipment that may be needed for a concrete job. These can include reinforcement bars, wire mesh or fiber mesh, concrete pumps or mixers, concrete vibrators, trowels, edgers, and finishing tools. The specific requirements will depend on the nature and scale of the project. It is important to carefully assess the project’s needs and include the cost of these additional materials and equipment in the quote. This will help ensure that the project is well-equipped and that the quote accurately reflects the total cost.

How can site-specific factors impact the cost of a concrete job?

Site-specific factors can have a significant impact on the cost of a concrete job. For example, if the site is hard to access or has limited space for equipment and materials, additional labor or special equipment may be required, which can increase the overall cost. Similarly, if the site has specific requirements, such as the need for a specific type of concrete mix or special finishing techniques, these factors should be taken into account when determining the quote. It is important to visit the site and assess any potential challenges or unique requirements to provide an accurate estimate of the cost.

What are some common mistakes to avoid when quoting concrete jobs?

When quoting concrete jobs, it is important to avoid certain common mistakes that can lead to inaccuracies or misunderstandings. One common mistake is failing to account for all the necessary materials and equipment, resulting in a lower quote that may not cover the actual cost. Similarly, not considering the complexity of the job or underestimating the labor required can lead to delays and additional expenses. Another mistake is not factoring in any potential site-specific factors, such as difficult access or special requirements, which can impact the overall cost. To provide an accurate quote, it is important to carefully assess all aspects of the project and avoid these common mistakes.