For any project involving steel fabrication, getting an accurate and competitive quote is essential. The quoting process can be complex, with various factors influencing the final cost. In this guide, we will explore some important tips and tricks to help you navigate the quoting process for steel fabrication.

First and foremost, it is important to have a clear understanding of the project requirements. This includes knowing the type and quantity of steel needed, as well as any specific design or customization requirements. Having this information upfront will enable you to provide accurate details to the fabricator, ensuring that you receive an accurate quote.

Another important factor to consider when quoting steel fabrication is the scope of the project. This includes the size and complexity of the steel components, as well as any additional services that may be required, such as welding or painting. By providing comprehensive information about the scope of the project, you can avoid any unexpected costs or delays in the fabrication process.

In addition, it is crucial to establish clear communication with the steel fabricator during the quoting process. This includes discussing any potential challenges or constraints that may impact the cost or timeline of the project. By maintaining open lines of communication, you can ensure that both parties are aligned on the project requirements and expectations.

Overall, successfully quoting steel fabrication requires a thorough understanding of the project requirements, clear communication with the fabricator, and careful consideration of the scope of work. By following these tips and tricks, you can increase your chances of receiving accurate and competitive quotes for your steel fabrication projects.

What is Steel Fabrication and Why is it Important?

Steel fabrication is the process of cutting, shaping, and assembling steel materials to create a final product. It involves various techniques such as welding, bending, drilling, and machining to transform raw steel into structures and components. This process is commonly used in industries such as construction, automotive, energy, and manufacturing.

Steel fabrication is important for several reasons:

- Durability: Steel is known for its strength and durability, making it a popular choice for creating structures that need to withstand heavy loads and harsh conditions.

- Flexibility: Steel can be easily manipulated and fabricated into different shapes and sizes, allowing for customization and versatility in design.

- Cost-effectiveness: Steel fabrication offers cost savings in the long run due to its low maintenance requirements and longevity.

- Efficiency: Steel fabrication allows for quicker construction and installation times, reducing overall project timelines.

- Sustainability: Steel is a recyclable material, making it an environmentally friendly choice compared to other construction materials.

The importance of steel fabrication cannot be overstated, as it plays a crucial role in the development of infrastructure, machinery, and various products. It enables the creation of strong and reliable structures that form the backbone of many industries.

Key Factors to Consider When Quoting Steel Fabrication Projects

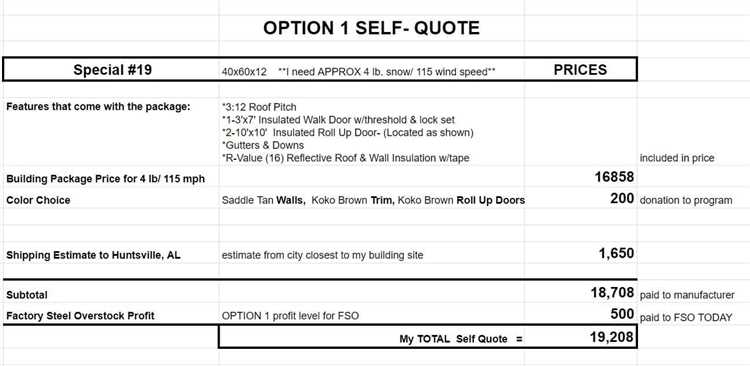

When it comes to quoting steel fabrication projects, there are several key factors that need to be considered in order to provide an accurate and competitive price. These factors include:

- Project Specifications: Understand the specific requirements of the project, including the type of steel, dimensions, and any special features or finishes. These specifications will affect the cost of materials and labor.

- Quantity: Determine the quantity of steel components needed for the project. This will help calculate the amount of raw materials required and the time it will take to fabricate them.

- Design Complexity: The complexity of the design will impact the cost of fabrication. Intricate designs and unique shapes may require specialized equipment or additional labor, which will increase the overall price.

- Production Schedule: Consider the timeline for the project. If a quick turnaround is required, it may necessitate additional resources or overtime work, which can affect the pricing.

- Quality Requirements: Determine the desired quality standards for the finished product. Higher specifications may require more precise fabrication techniques and additional inspections, resulting in higher costs.

In addition to these primary factors, there are several secondary factors to consider when quoting steel fabrication projects:

- Transportation: Calculate the cost of transporting the fabricated components to the project site. Distance, accessibility, and special handling requirements can impact the transportation cost.

- Overhead Costs: Consider the overhead costs associated with the fabrication facility, such as rent, utilities, equipment maintenance, and employee benefits.

- Market Conditions: Stay informed about the current steel market conditions, including fluctuations in material prices, labor costs, and availability. These factors can affect the overall pricing.

- Profit Margin: Determine the desired profit margin for the project. This will vary depending on the competitiveness of the market and the level of risk involved.

By carefully considering these key factors, steel fabricators can provide accurate and competitive quotes for their projects, ensuring customer satisfaction and profitability.

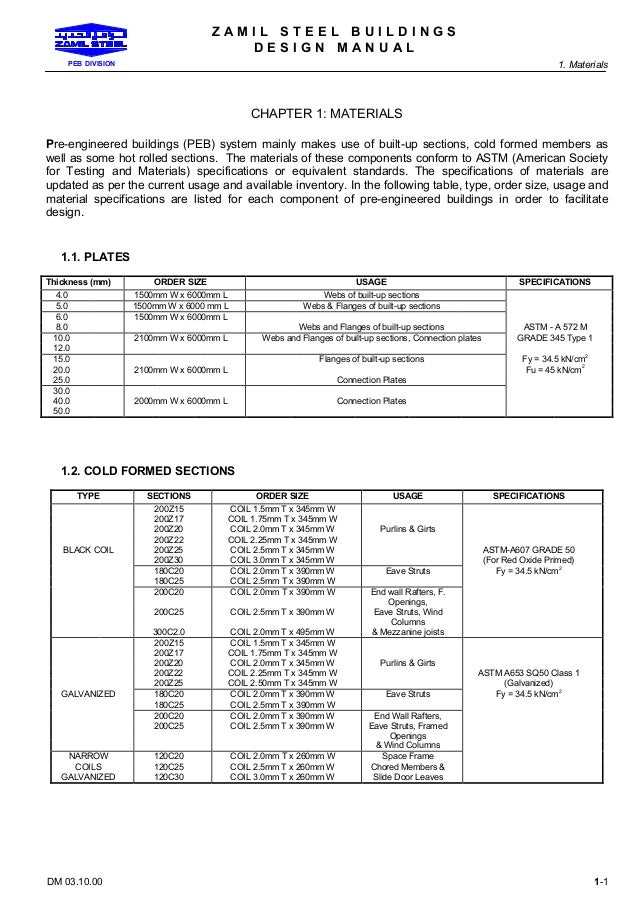

Understanding Different Types of Steel and their Impact on Fabrication Costs

When it comes to steel fabrication, it’s important to understand the different types of steel and how they can impact the overall costs of a project. Different types of steel have varying properties and characteristics that can affect the fabrication process and ultimately, the final cost.

1. Carbon Steel: Carbon steel is the most common type of steel used in fabrication. It is known for its high strength and durability, making it suitable for a wide range of applications. Carbon steel is also relatively inexpensive, which makes it a cost-effective choice for many projects.

2. Stainless Steel: Stainless steel is another popular choice for fabrication due to its corrosion resistance and aesthetic appeal. It contains a higher percentage of chromium, which gives it its unique properties. However, stainless steel tends to be more expensive than carbon steel, which can affect the overall cost of a project.

3. Alloy Steel: Alloy steel is made by combining carbon steel with other elements such as manganese, nickel, or chromium. This creates a material with enhanced properties such as increased strength, hardness, and resistance to wear and tear. The addition of these elements can also increase the cost of fabrication.

4. Tool Steel: Tool steel is a type of alloy steel that is specifically designed for the production of tools and dies. It has excellent hardness, wear resistance, and toughness, making it ideal for applications that require cutting, drilling, or shaping. However, tool steel is more expensive than other types of steel due to its specialized properties.

5. Galvanized Steel: Galvanized steel is coated with a layer of zinc to protect it from corrosion. This makes it highly durable and long-lasting, especially in outdoor environments. However, the process of galvanization adds an extra cost to the fabrication process.

Understanding the different types of steel and their impact on fabrication costs is crucial for accurately quoting a steel fabrication project. By considering factors such as the type of steel, its properties, and any additional processes required, fabricators can provide clients with a more precise and competitive quotation.

Effective Estimating Approaches for Steel Fabrication Quotations

When it comes to quoting steel fabrication projects, accurate estimating is crucial for both the client and the fabricator. A well-prepared quotation ensures that the client receives a fair and realistic price for the project, while the fabricator avoids any potential losses or disputes. Here are some effective estimating approaches to help you create accurate steel fabrication quotations.

- Thoroughly review the project specifications:

- Break down the project into components:

- Consider material costs:

- Account for labor and equipment costs:

- Include overheads and profit margin:

- Get input from the production team:

- Provide a detailed breakdown in the quotation:

Before starting the estimating process, carefully review the project specifications provided by the client. Take note of important details such as material type, dimensions, welding requirements, surface finish, and any additional requirements or challenges. This step ensures that you have a clear understanding of the project scope.

To estimate the cost accurately, break down the project into its various components. This can include individual parts, assemblies, or even sections of structures. Breaking down the project allows you to assign costs to each component based on material quantity, labor hours, production processes, and any additional costs such as outsourcing or transportation.

One of the significant factors in steel fabrication quotations is the cost of materials. Research the current market prices for the specific material required for the project and build that into your estimation. Take into account any wastage, scrap, or offcuts that may result during the fabrication process.

Labor and equipment costs also play a vital role in the overall quotation. Estimate the number of labor hours required for each component and multiply it by the hourly rate. Additionally, consider any specialized equipment or machinery needed for the project and factor in the costs of their usage, maintenance, and operator wages.

Don’t forget to account for your overhead expenses such as rent, utilities, insurance, and administrative costs. Add a reasonable profit margin to cover your business expenses and ensure healthy profitability. Be sure to strike a balance between a competitive price and ensuring that your business remains sustainable.

When estimating a steel fabrication project, it’s essential to involve the production team. Their insights and expertise can help identify any potential pitfalls, challenges, or opportunities for optimization. Their input can also provide valuable information regarding production timelines, efficiencies, and potential cost-saving measures.

Lastly, present your quotation in a clear and detailed manner. Break down the costs by components, material quantities, labor hours, and any additional expenses. This level of transparency not only instills confidence in the client but also allows them to understand the breakdown of costs and make informed decisions.

By following these effective estimating approaches, you can create accurate steel fabrication quotations that benefit both your business and your clients. Remember to always stay updated on market trends, keep track of industry benchmarks, and continuously evaluate and refine your estimating process to ensure long-term success.

Top Tips for Accurate Quantity Takeoffs in Steel Fabrication Quotes

To ensure accurate quantity takeoffs in your steel fabrication quotes, it’s important to follow these top tips:

- Review the project drawings and specifications: Carefully go through the project drawings and specifications to understand the scope and requirements of the steel fabrication. Pay attention to details such as dimensions, materials, finishes, and any specific instructions.

- Create a standardized checklist: Develop a checklist of commonly used steel fabrication items, such as beams, columns, plates, and connections. This will help you systematically identify and quantify the required components.

- Take accurate measurements: Use precise measuring tools, such as tape measures and calipers, to take accurate measurements of the required steel components. Ensure you measure length, width, height, thickness, and any other relevant dimensions as specified in the drawings.

- Consider fabrication and erection requirements: Take into account the fabrication and erection requirements when quantifying the steel components. For example, if connections or welding are required, make sure to include them in your quantity takeoff.

- Account for material waste: Steel fabrication often involves some degree of material waste, such as excess cut-off pieces or scrap. Factor in an appropriate allowance for waste when determining the quantity of steel required.

- Double-check your calculations: Before finalizing the quantity takeoff, double-check your calculations to ensure accuracy. Verify measurements, quantities, and any formulas or equations used during the estimation process.

- Use software tools: Consider utilizing specialized software tools for quantity takeoffs in steel fabrication. These tools can automate calculations, store relevant data, and improve the overall accuracy and efficiency of the estimation process.

- Continuously update your knowledge: Stay updated with the latest trends, techniques, and standards in steel fabrication. Regularly attend training sessions, industry conferences, and workshops to enhance your skills and improve the accuracy of your quantity takeoffs.

By following these top tips, you can improve the accuracy of your quantity takeoffs in steel fabrication quotes, leading to more reliable estimates and better project outcomes.

The Role of Material Finishes in Steel Fabrication Quotations

When providing a quotation for a steel fabrication project, it is important to consider the role of material finishes. Material finishes not only affect the appearance of the final product but also influence its durability and performance. Here are some key points to consider when including material finishes in your quotations:

- Surface Preparation: The first step in achieving a high-quality material finish is proper surface preparation. This includes cleaning, degreasing, and removing any mill scale or rust to ensure a smooth and even surface for the finish to adhere to.

- Painting and Coating: Painting and coating are common material finishes that provide protection against corrosion and enhance the aesthetic appeal of the steel. The type of paint or coating used depends on the specific requirements of the project, such as the environment the steel will be exposed to or the desired color and finish.

- Galvanizing: Galvanizing is a popular material finish that involves coating the steel with a layer of zinc to provide enhanced corrosion protection. This process is often used for structural steel components that will be exposed to harsh environments, such as bridges or outdoor structures.

- Powder Coating: Powder coating is an environmentally friendly material finish that involves applying a dry powder to the steel surface, which is then cured to form a durable, attractive finish. It offers excellent resistance to chipping, fading, and scratching.

- Brushed and Polished Finishes: For projects that require a more decorative or architectural appearance, brushed or polished finishes can be applied to the steel surface. These finishes provide a smooth and reflective surface that can be visually appealing, but they may require additional maintenance to preserve their appearance.

When providing a quotation, it is important to accurately estimate the cost and time required for the desired material finishes. Factors such as the size and complexity of the project, the type of finish required, and any special handling or treatment needed should be taken into account. By considering the role of material finishes, you can provide your clients with accurate and comprehensive quotations for their steel fabrication projects.

How to Factor in Labor Costs and Turnaround Time when Quoting Steel Fabrication

Quoting steel fabrication accurately requires considering both labor costs and turnaround time. These factors are crucial in determining the profitability and feasibility of a project. Here are some tips to help you factor in labor costs and turnaround time effectively:

- Review project specifications: Carefully review the project specifications and scope of work to understand the complexity and requirements of the job. This will help you estimate the amount of labor needed and the time it will take to complete the fabrication process.

- Estimate the labor hours: Calculate the number of labor hours required for each task involved in the steel fabrication process. Break down the work into specific activities such as cutting, welding, forming, and finishing. Consult with experienced fabricators or your team to obtain accurate estimations.

- Determine the labor rate: Determine the labor rate for your fabrication team. This rate should account for factors such as skill level, experience, and market rates. Consider any additional costs, such as employee benefits, overtime, or subcontracting.

- Calculate labor costs: Multiply the estimated labor hours for each task by the labor rate to calculate the labor costs for that specific activity. Sum up the costs for all the tasks to obtain the total labor cost for the steel fabrication project.

- Consider turnaround time: Evaluate the project schedule and timeline requirements. Determine if there are any deadlines or time constraints that may affect the labor costs. Shorter turnaround times often require additional labor resources or overtime, which can impact the final quote.

- Account for contingency: Include a contingency factor in your labor cost estimation to account for unexpected delays, overtime, or rework. It is wise to allocate a certain percentage of the total labor cost as a contingency to mitigate the risk of unforeseen circumstances.

- Ensure accuracy: Double-check your labor cost calculations and consider seeking input from other knowledgeable professionals within your organization. Ensuring accuracy in your quoting process will help you avoid underestimating labor costs and potentially losing money on a project.

By factoring in labor costs and turnaround time when quoting steel fabrication, you can provide accurate estimates that consider the true cost of the project. This will help you make informed pricing decisions and increase the chances of securing profitable contracts.

Common Mistakes to Avoid When Quoting Steel Fabrication Projects

Quoting steel fabrication projects can be a complex task, and it’s important to avoid common mistakes that can lead to costly errors and delays. Here are some key mistakes to avoid when quoting steel fabrication projects:

- Inaccurate Measurements: One of the most common mistakes is providing inaccurate measurements or failing to account for variations in dimensions. It’s crucial to take precise measurements and consider any tolerances that may be required.

- Not Considering Design Changes: Ignoring design changes or failing to incorporate them into the quote can lead to unexpected costs down the line. It’s essential to carefully review all the project specifications and make adjustments accordingly.

- Underestimating Material Costs: Failing to accurately estimate the cost of materials can result in underquoting and potentially losing profits. It’s important to research current market prices and account for any additional expenses such as transportation or storage.

- Not Factoring in Labor Costs: Forgetting to include labor costs in the quote can lead to financial loss. Take into account the expertise and time required for each stage of fabrication to ensure accurate pricing.

- Ignoring Project Complexity: Overlooking the complexity of a project can lead to underestimating the time and effort required, as well as the associated costs. Ensure a thorough understanding of the project complexity to provide an accurate quote.

- Failure to Account for Project Deadlines: Not considering project deadlines when providing a quote can result in unrealistic expectations and potential time constraints. Make sure to factor in the required lead time for fabrication and delivery.

- Not Accounting for Quality Control: Neglecting to consider quality control measures can lead to rework or rejection of fabricated components, resulting in additional costs. It’s important to allocate resources for quality assurance and inspections.

Avoiding these common mistakes can help ensure accurate and profitable quotes for steel fabrication projects. It’s important to carefully review project specifications, take precise measurements, consider all costs involved, and thoroughly assess project complexity. By doing so, you can provide quotes that are comprehensive, realistic, and financially viable.

Question and answer:

What is steel fabrication?

Steel fabrication involves the creation of structures or components from steel through various processes such as cutting, bending, and welding. It is a common method used in construction and manufacturing industries.

What are some factors to consider when quoting steel fabrication?

When quoting steel fabrication, it is important to consider factors such as the complexity of the project, the amount of steel required, the cost of materials, labor, and delivery, as well as overhead costs and profit margin.

How can accuracy be ensured when quoting steel fabrication?

Accuracy in quoting steel fabrication can be ensured by carefully reviewing project specifications, conducting site visits if necessary, accurately estimating material quantities, accounting for labor and overhead costs, and double-checking all calculations before submitting the quote.

What are some tips for effectively quoting steel fabrication?

Some tips for effectively quoting steel fabrication include: conducting a thorough review of project requirements, estimating material quantities accurately, considering all costs involved, including labor and overhead, staying up to date with current market prices, and regularly reviewing and adjusting quoting processes for improved efficiency.